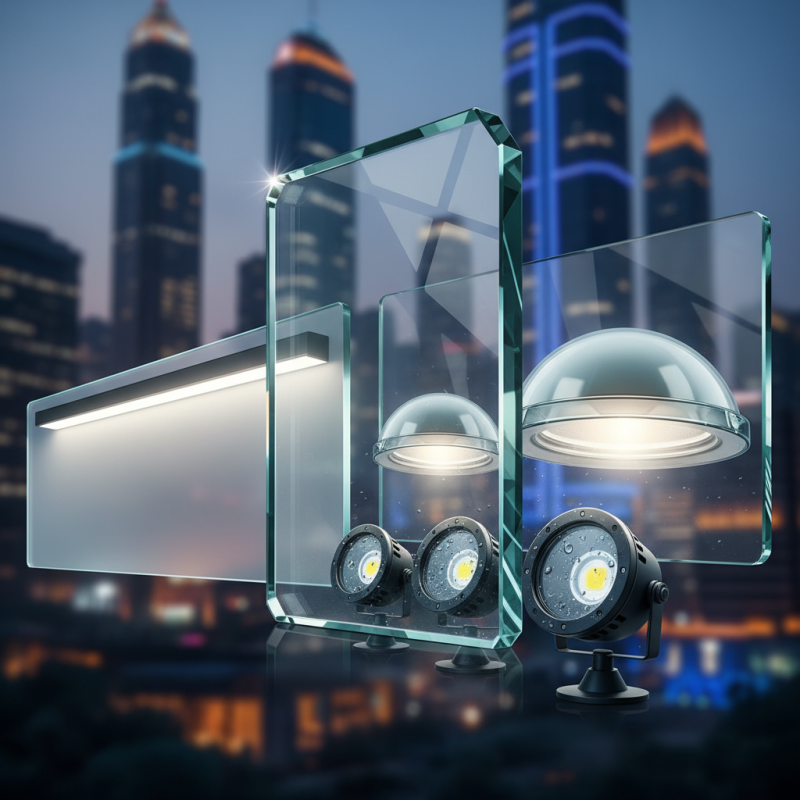

Toughened Glass For LED Lighting is gaining traction in various industries due to its numerous advantages. According to the latest industry report by Allied Market Research, the global toughened glass market is expected to reach $92 billion by 2025. This growth is fueled by the rising demand for sustainable and energy-efficient materials in lighting applications.

Industry expert Dr. Emily Carter states, "Toughened glass not only enhances durability but also improves the aesthetic appeal of LED lighting designs." This statement highlights a vital aspect of toughened glass. It withstands extreme temperatures and impacts, making it ideal for LED environments.

Incorporating toughened glass can reduce the risks associated with traditional materials. This innovative glass type minimizes glare and maximizes light transmission. However, it is crucial to recognize that not all applications may benefit equally. The cost and availability can pose challenges. As we explore the top ten benefits, an honest evaluation of toughened glass is needed.

Toughened glass offers significant advantages in energy efficiency for LED lighting. Its durability makes it ideal for various environments. This type of glass effectively insulates heat, reducing energy loss. As a result, it enhances the overall performance of LED fixtures. Toughened glass can withstand extreme temperatures without breaking down. This feature prolongs the lifespan of both the glass and the lighting system.

Another notable benefit is its ability to diffuse light evenly. This characteristic enhances the aesthetic appeal of lighting installations. Even light distribution means reduced hotspots and glare. Such improvements contribute to energy efficiency by optimizing the use of LED technology. Additionally, toughened glass is often more resistant to scratches. This quality maintains clarity over time, enhancing the effectiveness of lighting.

However, while toughened glass has its advantages, it is essential to consider its limitations. There may be higher initial costs compared to standard glass. This might affect budget decisions for some projects. The production of toughened glass can also be energy-intensive. Balancing these factors is crucial when integrating toughened glass into LED lighting setups. Adjusting approaches ensures that energy efficiency aligns with budget constraints and sustainability goals.

| Benefit | Description | Energy Efficiency Impact |

|---|---|---|

| High Durability | Toughened glass is resistant to impact and thermal stress. | Reduction in maintenance costs and energy used in replacements. |

| Safety | If broken, it shatters into small, safe pieces. | Promotes safer environments for energy-saving installations. |

| Thermal Regulation | Better thermal insulation properties. | Improves efficiency of LED lights by reducing heat loss. |

| UV Protection | Blocks harmful ultraviolet rays. | Protects energy-efficient materials and prolongs life. |

| Aesthetic Appeal | Modern and sleek appearance enhances design. | Encourages adoption of LED solutions in stylish spaces. |

| Light Transmission | High levels of light transmission without distortion. | Maximizes the effectiveness of LED lighting. |

| Energy Savings | Reduces reliance on artificial lighting. | Leads to lower energy bills. |

| Environmentally Friendly | Made from recyclable materials. | Supports sustainable building practices. |

| Cost-Effectiveness | Long-lasting, reducing frequent replacement costs. | Maximizes return on investment in lighting solutions. |

Toughened glass plays a crucial role in enhancing safety standards in LED lighting applications. It is better able to resist impact, heat, and environmental stressors. This resilience reduces the risk of shattering, which can lead to dangerous situations. LEDs are often used in public spaces, where safety is paramount. Using toughened glass helps to meet these high safety requirements.

However, it’s important to acknowledge that not all applications see the same benefits. In some cases, the thickness of toughened glass can affect light diffusion. This may lead to uneven lighting, creating glare in specific areas. Designers must balance safety with aesthetics for optimal outcomes. Sometimes, it feels like a compromise, but careful consideration can yield good results.

Moreover, toughened glass can be heavier than standard options. This added weight can strain fixtures and mounting systems. It is essential to ensure that they are engineered to support this weight, or safety risks could arise. Addressing these issues can enhance both safety and functionality in lighting designs.

Toughened glass proves essential for LED lighting applications, enhancing both durability and longevity in fixtures. Unlike standard glass, toughened glass undergoes a strengthening process, making it resistant to impact and thermal stress. Research indicates that it can withstand forces up to five times greater than regular glass. This increased robustness is especially important in environments prone to breaking and wear.

LED fixtures benefit significantly from toughened glass. The lifespan of LED lamps can extend when housed in high-quality materials. According to industry reports, toughened glass has a heat resistance of around 300°C. This capability helps maintain consistent performance in various conditions. Moreover, the UV resistance of toughened glass minimizes degradation over time, ensuring longevity for the lighting system.

**Tips:** Always check for the glass's certification. It should meet safety standards for best results. Regular maintenance, such as cleaning, also helps in assessing any wear or damage. Lastly, consider the environmental factors where the lights will be installed. This knowledge can influence your choice of materials.

Toughened glass has become essential in LED lighting design. Its strength and durability are well-documented. For example, studies show that toughened glass can withstand temperature changes up to 300°C. This trait allows for innovative designs in various settings, such as commercial and residential spaces. The aesthetic appeal of toughened glass makes lighting fixtures visually stunning.

The transparency of toughened glass enhances light diffusion. This results in smoother, more uniform illumination. Reports indicate that using toughened glass can increase light efficiency by up to 20%. This not only improves the overall aesthetic but also contributes to energy savings in the long run. However, achieving the right thickness and finish can be challenging. Designers must be mindful of these factors during selection and implementation.

Tips: Consider the integration of colored or frosted toughened glass for unique effects. Experiment with different textures as well. Remember, while toughened glass offers many benefits, it requires careful handling during installation. Always assess the space and lighting needs before making a final decision.

Toughened glass plays a crucial role in managing heat for LED lighting. LEDs generate significant heat, which can impact their performance and longevity. Toughened glass provides effective thermal resistance, helping to disperse heat efficiently. This feature is vital in preventing overheating, which can lead to reduced brightness and shorter lifespan.

The unique properties of toughened glass also enhance durability. It can withstand high temperatures and sudden changes in heat without cracking. This is crucial for environments with fluctuating temperatures. However, not all toughened glass is created equal. There can be variations in quality. Some may not perform as well under stress, leading to potential failures.

Choosing the right type of toughened glass requires careful consideration. You must assess the specific needs of your LED application. A common mistake is underestimating the thermal expansion that occurs during operation. This oversight can lead to inadequate heat management. Ultimately, understanding these factors will help in making more informed decisions.