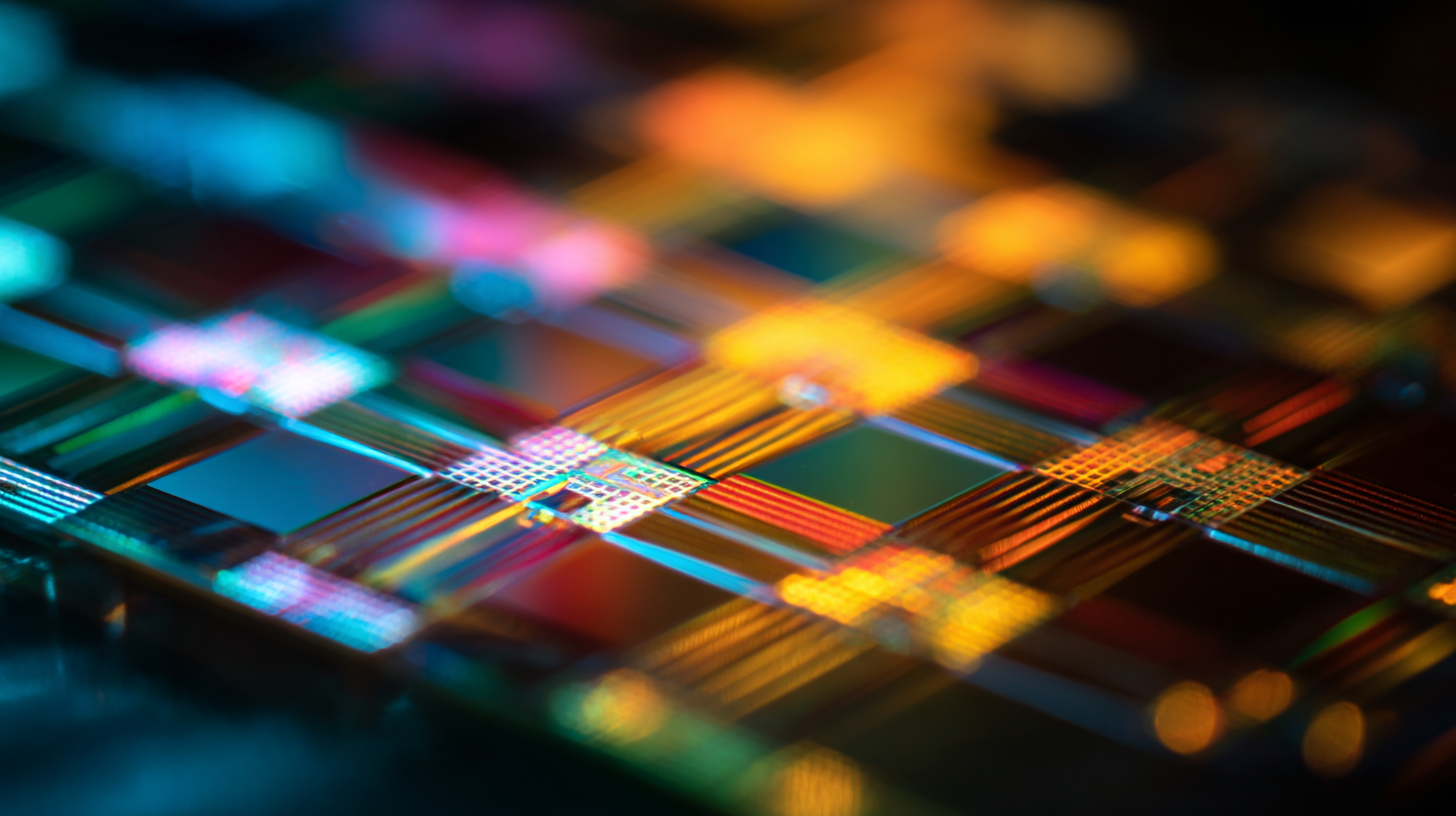

In the rapidly evolving landscape of modern electronics and green technologies, the significance of innovative materials cannot be overstated. Among these, Ito Conductive Glass has emerged as a transformative element, owing to its unique properties that bridge the gap between functionality and sustainability. This specialized glass, composed of indium tin oxide, offers exceptional electrical conductivity while maintaining transparency, making it an ideal choice for applications ranging from touchscreens and solar cells to energy-efficient displays. As we delve into the advantages of Ito Conductive Glass, we will explore how its integration into various technologies not only enhances performance but also contributes to the development of eco-friendly solutions. This "How to" guide aims to illuminate the myriad benefits and applications of Ito Conductive Glass, providing insights into its pivotal role in advancing both electronic innovation and green technology principles.

The rise of indium tin oxide (ITO) conductive glass in electronic applications reflects a significant shift toward high-performance materials that meet modern technological demands. The transparent conductive film market is poised for robust growth, with projections estimating its value to reach approximately $4.2 billion by 2025, driven primarily by increasing applications in consumer electronics, automotive sectors, and smart technologies. The market’s shift toward ITO and other metal oxides is spurred by the need for superior conductivity and transparency, making these materials ideal for touch screens, displays, and photovoltaic cells.

Moreover, the competitive landscape is evolving with advancements in alternative materials such as silver nanowires, carbon nanotubes, and metal meshes. These emerging technologies provide unique properties that challenge traditional ITO usage while diversifying applications across automation and advanced electronics. As manufacturers seek cost-effective and sustainable solutions, the integration of ITO conductive glass will remain crucial, ensuring that devices can maintain efficiency while adhering to green technology standards. The continued exploration of ITO's capabilities will play a vital role in shaping the future of electronics.

Indium Tin Oxide (ITO) conductive glass has emerged as a pivotal material in the realm of renewable energy solutions. Its unique properties, such as high transparency and excellent electrical conductivity, make it an ideal candidate for solar cells, particularly thin-film photovoltaics. By enhancing light absorption while providing effective charge transport, ITO conductive glass maximizes the efficiency of solar panels, enabling them to convert more sunlight into energy. This synergy not only boosts energy output but also contributes to the reduction of the overall cost of solar energy systems.

In addition to its application in solar energy, ITO conductive glass plays a crucial role in the development of energy-efficient displays and smart windows. These innovations are essential for advancing green technologies, as they reduce energy consumption in buildings and contribute to better thermal management. Smart windows equipped with ITO can adapt to varying light conditions, decreasing the need for artificial lighting and thereby lowering energy usage. This versatility positions ITO conductive glass at the forefront of the green technology movement, fostering a more sustainable and efficient energy landscape.

Indium Tin Oxide (ITO) conductive glass has emerged as a game-changer in the electronics industry, especially when compared to traditional materials like metal films and carbon-based alternatives. One of the standout benefits of ITO is its excellent optical transparency combined with electrical conductivity. This makes it particularly suitable for applications in touch screens, solar cells, and display technologies, where clarity and conductivity are crucial. In contrast, traditional materials often compromise on one aspect, either being too opaque or lacking sufficient conductivity, which limits their effectiveness in modern electronic applications.

When considering alternatives, it's essential to evaluate the long-term sustainability of materials. ITO is not only efficient but also compatible with green technologies. It can be produced with lower environmental impact compared to some traditional materials, making it a preferable choice for eco-conscious manufacturers.

**Tip:** Always research the lifecycle impact of materials before making a decision for your project; consider not just performance but also environmental implications.

Moreover, the process of integrating ITO into electronic devices often leads to lighter and thinner designs, which are increasingly demanded in the market. This contrasts sharply with some conventional materials that can add significant bulk to devices.

**Tip:** For optimal performance, ensure that your manufacturing processes are adapted to maximize the benefits of ITO, such as using proper deposition techniques that enhance its conductivity and transparency.

| Property | ITO Conductive Glass | Traditional Conductive Materials |

|---|---|---|

| Electrical Conductivity (Ω·cm) | 10-4 to 10-3 | 10-2 to 10-1 |

| Transparency (%) | 80 - 90 | 55 - 75 |

| Flexibility | High | Low |

| Environmental Impact | Low | Moderate to High |

| Manufacturing Cost (per sq meter) | $50 - $100 | $20 - $60 |

| Applications | Smartphones, Touchscreens, Solar Cells | Displays, PCB Circuits, Power Distribution |

The future of Ito conductive glass technology holds immense potential as innovations continue to reshape the landscape of modern electronics and green technologies. With the increasing demand for energy-efficient systems, Ito conductive glass is paving the way for advancements in solar cells, touchscreens, and smart window technologies. This remarkable material not only enhances conductivity but also maintains transparency, making it an ideal choice for integrating electronics seamlessly into our daily lives.

**Tips:** When considering the implementation of Ito conductive glass in your projects, focus on its compatibility with various substrates to maximize performance. Moreover, pay attention to the specifications regarding its deposition methods, as improved techniques can significantly enhance the durability and efficiency of the final product.

As research progresses, we're likely to see more collaborative efforts between industries to harness the capabilities of Ito conductive glass. For instance, its integration into building materials could lead to the development of energy-efficient facades that contribute to sustainable architecture. Additionally, the exploration of novel applications in wearable technology and smart devices indicates a trend towards a more interconnected and tech-driven future.

**Tips:** Stay abreast of the latest trends in Ito conductive glass applications by following industry publications and attending relevant conferences. Engaging with the community can provide valuable insights into emerging techniques and materials that complement the performance of Ito glass in innovative ways.

The production of ITO (indium tin oxide) conductive glass has traditionally raised concerns regarding environmental sustainability due to the extraction and processing of rare metals. However, recent advancements in eco-friendly manufacturing practices are transforming the industry. These practices emphasize the use of non-toxic materials and renewable energy sources, minimizing the environmental footprint associated with ITO glass production. By adopting techniques such as green chemistry and solvent-free processes, manufacturers are able to significantly reduce hazardous waste and emissions.

In addition to reducing environmental impacts, these sustainable methods contribute to resource efficiency. For instance, recycling indium from e-waste can serve as a viable alternative to mining, supporting a circular economy. Moreover, innovations in the production process, such as the use of bio-based materials and energy-efficient technologies, not only enhance the sustainability of ITO glass but also improve its overall performance in applications like touch screens and solar cells. By focusing on eco-friendly manufacturing practices, the industry can lead the way toward greener electronics, ensuring that technological advancement aligns with environmental stewardship.