The glass deep processing industry has been experiencing remarkable advancements, driven by technological innovations and increasing demand across various sectors. According to a recent market analysis by ResearchAndMarkets, the global glass processing market is expected to reach $135 billion by 2026, growing at a CAGR of 4.3%. This growth trajectory underscores the critical role that glass deep processing plays in enhancing product performance and meeting evolving consumer preferences.

In light of these trends, the year 2025 is poised to unveil groundbreaking innovations that will redefine the capabilities of glass deep processing technologies. From automated cutting and finishing techniques to eco-friendly production methods, these advancements promise not only to improve efficiency but also to minimize environmental impact. As industries seek to incorporate more sustainable practices, the latest technologies in glass processing are set to become pivotal in achieving these goals.

In this context, understanding the top innovations in glass deep processing technologies for 2025 is essential for industry stakeholders looking to maintain a competitive edge. This exploration will highlight how these innovations can transform manufacturing processes, enhance product quality, and align with the sustainability imperatives of modern industry.

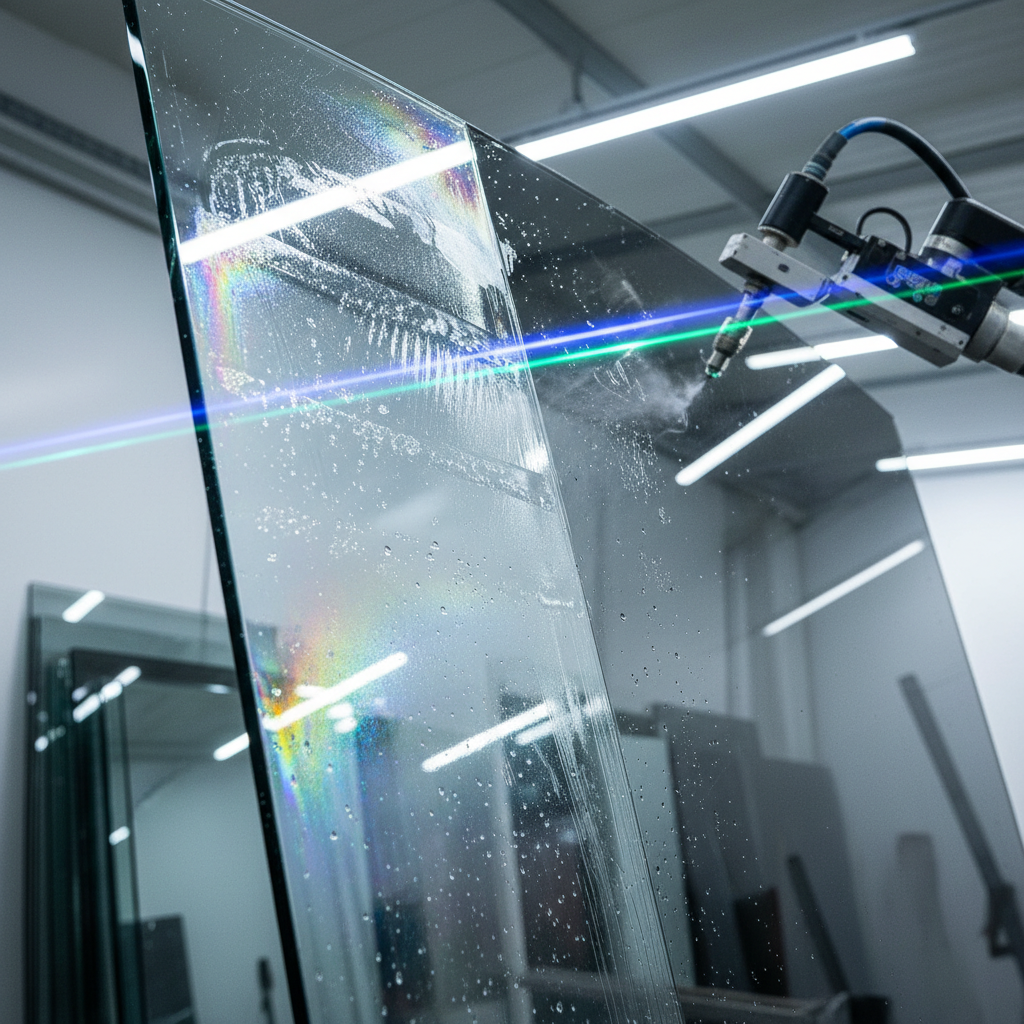

As we look towards 2025, the glass industry is on the brink of remarkable innovations in cutting and shaping techniques. These advancements are set to enhance precision, reduce waste, and create opportunities for more intricate designs. One standout innovation is the use of laser cutting technology, which allows for unparalleled accuracy in shaping glass. This technique not only minimizes the risk of breakage but also enables the creation of complex patterns that were previously challenging to achieve.

Incorporating digital tools into glass processing is another trend that promises to revolutionize the industry. Computer numerical control (CNC) machines equipped with advanced software can now craft custom glass pieces with ease. This digital transformation streamlines the production process and provides designers with the flexibility to experiment with new forms, ensuring that each piece is truly unique.

Tips for success: When working with advanced cutting technologies, regularly calibrate your equipment to maintain precision. Additionally, consider investing in training for your team to stay abreast of new techniques and software updates. Engaging with industry innovations can inspire creative approaches and help businesses remain competitive in this evolving field.

Recent advancements in coatings and treatments for glass deep processing technologies have significantly enhanced the durability and performance of glass products. Innovations such as nano-coatings and hydrophobic treatments are at the forefront, providing superior protection against scratches, stains, and weathering. These advanced coatings not only improve the physical resilience of glass but also contribute to aesthetic appeal by maintaining clarity and shine over time.

Moreover, the introduction of self-healing coatings represents a remarkable leap forward in glass technology. These smart materials possess the ability to repair minor scratches and damages autonomously when exposed to heat or sunlight. This feature not only extends the lifespan of glass products but also minimizes maintenance costs for consumers and industries alike. As the demand for high-performance glass continues to grow, the integration of these advanced coatings and treatments is proving essential for meeting modern architectural and industrial demands.

In 2025, smart glass technologies are set to revolutionize the way we interact with our environments. These innovations promise enhanced efficiency and responsiveness, allowing for dynamic control over light, heat, and privacy. Technologies such as electrochromic and photochromic glass are becoming increasingly sophisticated, automatically adjusting their properties in response to changes in light or temperature. This not only improves energy efficiency in buildings but also elevates the user experience in both residential and commercial spaces.

Tip: When considering the integration of smart glass, evaluate the specific needs of your environment. For instance, in office buildings, opt for technologies that improve natural light utilization while reducing glare and heat. In residential settings, consider glass that adjusts to ambient conditions, enhancing comfort and privacy.

Furthermore, these advancements in glass processing are paving the way for more sustainable building practices. By incorporating smart glass solutions, structures can significantly decrease their reliance on artificial lighting and climate control systems, ultimately reducing energy consumption. This shift not only aligns with global sustainability goals but also provides a competitive edge in the market.

Tip: Collaborate with experienced architects and engineers to select the right smart glass technologies for your project. An informed choice can maximize both functionality and aesthetic appeal while contributing to greener living spaces.

The glass industry is witnessing a significant transformation as sustainable practices in glass recycling and production methods take center stage. According to the Glass Packaging Institute, over 80% of glass can be recycled indefinitely without losing quality, making it a highly sustainable option for manufacturers and consumers alike. Advanced recycling technologies are emerging, enabling manufacturers to reuse cullet (recycled glass) effectively in their production processes, reducing energy consumption by up to 30% compared to processing virgin materials.

Tips: Consider participating in local glass recycling programs. Many cities offer drop-off points, which can significantly reduce the environmental impact of waste glass. Additionally, consumers can check for locally-sourced glass products, supporting businesses that prioritize sustainability.

Innovative production methods such as the use of renewable energy sources are also on the rise. A report by the International Energy Agency noted that the glass industry could potentially reduce CO2 emissions by 15% by integrating solar or wind energy into its production lines. These advances not only enhance the environmental footprint of glass production but also open doors for cost savings in manufacturing facilities.

Tips: Explore products made from recycled glass, such as tiles and countertops. Not only do these items prevent waste, but they also often come with a unique aesthetic that can enhance your living space.

This bar chart represents the top 5 innovations in glass deep processing technologies with a focus on sustainable practices in glass recycling and production methods. The data illustrates the percentage increase in efficiency and sustainability by 2025.

The integration of artificial intelligence (AI) and automation in glass manufacturing processes is revolutionizing the industry by enhancing efficiency and precision. AI technologies, such as machine learning algorithms, are being employed to predict product quality and optimize production schedules. By analyzing historical data and real-time inputs, AI systems can identify potential defects before they occur, enabling manufacturers to take corrective actions proactively. This not only minimizes waste but also ensures a higher consistency in product quality.

Furthermore, automation is streamlining various stages of glass deep processing, from cutting and shaping to coating and finishing. Automated systems equipped with robotic arms and advanced sensors can operate at speeds and accuracies that far exceed human capability. This fusion of AI and automation allows for a fully integrated production line where machines communicate and adapt to changing conditions autonomously. As a result, manufacturers can achieve significant reductions in labor costs and lead times, paving the way for more sustainable and flexible production environments. The future of glass processing is undoubtedly intertwined with these cutting-edge technologies, setting the stage for an innovative era in the glass industry.

| Innovation | Description | Advantages | Impact on Industry |

|---|---|---|---|

| AI-Driven Quality Control | Utilization of AI algorithms to detect defects in glass products. | Increased accuracy in quality assessment and reduced waste. | Enhances product durability and customer satisfaction. |

| Automated Glass Cutting | Robotic solutions for precise and efficient glass cutting tasks. | Higher production efficiency and reduced labor costs. | Streamlines the manufacturing process significantly. |

| Smart Coating Technologies | Advanced coatings applied via automated systems for thermal and UV resistance. | Improves energy efficiency and glass longevity. | Spurs innovation in energy-efficient architectural designs. |

| Real-Time Production Monitoring | Integration of IoT devices for constant monitoring of production metrics. | Immediate response to production anomalies and reduced downtime. | Enhances overall operational efficiency and transparency. |

| Enhanced Recycling Processes | Technologies promoting better breakdown and repurposing of glass materials. | Supports sustainability and reduces raw material costs. | Aligns industry practices with environmental regulations. |