The rapidly evolving landscape of sustainable industry innovations sees a growing emphasis on efficient and eco-friendly practices, particularly in the realm of manufacturing. One significant area poised for transformation is Glass Deep Processing, which encompasses advanced techniques for enhancing the functionality and aesthetic qualities of glass products. As we approach 2025, the integration of cutting-edge technologies and sustainable practices in Glass Deep Processing is expected to drive significant changes, reflecting a broader commitment to environmental stewardship across various sectors.

This exploration of the top trends in Glass Deep Processing illuminates the pivotal role that innovation plays not only in manufacturing efficiency but also in reducing carbon footprints and promoting recyclability. With increasing global awareness of environmental issues, manufacturers and researchers are prioritizing methods that minimize waste and maximize the lifecycle of glass materials. Through collaborations and advancements in materials science, we anticipate breakthroughs that will redefine applications and elevate glass to new heights in construction, consumer products, and beyond.

As we delve deeper into the anticipated trends of 2025, we will uncover how Glass Deep Processing is positioned to lead the charge towards a more sustainable future, showcasing the synergy between technological advancement and environmental responsibility. This journey highlights the transformative potential of glass in meeting modern demands, paving the way for innovative solutions that harmonize industrial growth with ecological awareness.

The landscape of glass deep processing is on the verge of transformation as we approach 2025, driven by emerging technologies that prioritize sustainability. One significant trend is the integration of smart manufacturing techniques, such as automation and artificial intelligence, to enhance efficiency in glass production. These technologies facilitate precise control over the processing stages, ensuring minimal waste and optimized energy consumption. Furthermore, the incorporation of recyclable materials into glass products is gaining traction, leading to a circular economy model that promotes sustainability within the industry.

In addition to smart manufacturing, advancements in nanotechnology are set to revolutionize glass properties, making it more resilient and energy-efficient. This includes the development of self-cleaning and anti-reflective coatings that reduce maintenance costs and energy usage. Another noteworthy technology is the use of 3D printing in glass fabrication, providing unparalleled design flexibility and reducing material waste. As these innovations mature, they will not only enhance the functionality of glass products but also contribute significantly to the industry's overall sustainability goals, positioning glass deep processing as a pivotal player in the green technologies of the future.

| Trend | Description | Impact on Sustainability | Emerging Technologies |

|---|---|---|---|

| Recycling Innovations | Advanced systems for recycling post-consumer glass products. | Reduces landfill waste and carbon emissions. | AI-driven sorting technologies. |

| Eco-Friendly Coatings | Use of sustainable materials for glass coatings. | Minimizes toxic substances and enhances recyclability. | Biodegradable coating technologies. |

| Energy-Efficient Manufacturing | Techniques to reduce energy consumption in glass production. | Lowers carbon footprint and operating costs. | High-efficiency furnaces. |

| Smart Glass Technologies | Glass that can change properties based on environmental conditions. | Improves energy efficiency in buildings. | Electrochromic and thermochromic glass. |

| 3D Glass Printing | Additive manufacturing processes for customized glass products. | Reduces waste and allows for innovative designs. | Binder jetting and extrusion technologies. |

The glass manufacturing industry is undergoing a transformative shift towards sustainability, spearheading innovative materials and techniques that align with environmental goals. One notable trend is the increasing use of recycled glass, which not only reduces waste but also conserves energy during production. By incorporating post-consumer glass into the manufacturing process, companies can significantly lower their carbon footprint, as melting recycled glass requires less heat than processing raw materials. This practice not only reinforces the circular economy but also appeals to consumers who prioritize eco-friendly products.

In addition to using recycled materials, advancements in production techniques are crucial for fostering sustainability in glass deep processing. Technologies such as automated cutting and shaping reduce waste and increase efficiency, allowing manufacturers to optimize resource use. Furthermore, adopting renewable energy sources, such as solar or wind power, for glass production is becoming more prevalent. These innovations not only enhance the industry's sustainability profile but also pave the way for more responsible manufacturing practices that can lead to long-term environmental benefits. The focus on sustainable materials and techniques signifies a promising future that aligns industrial growth with ecological preservation.

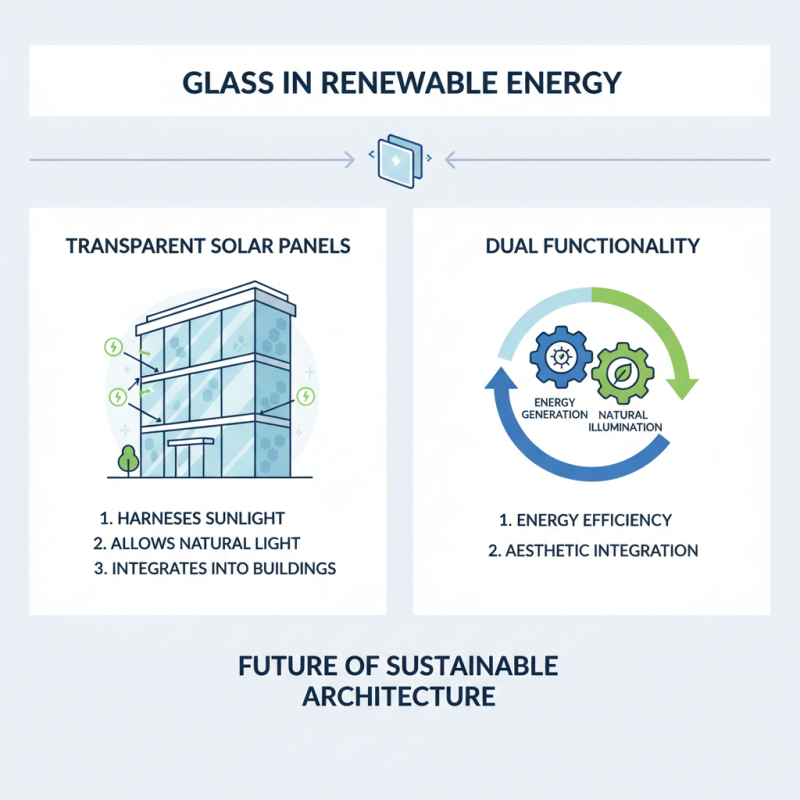

Innovative applications of glass are emerging as pivotal solutions in the renewable energy sector, showcasing the material's versatility and sustainability. One primary development involves the use of glass in photovoltaic systems. Transparent solar panels are being engineered to harness sunlight while allowing natural light to penetrate buildings, which enhances energy efficiency without compromising aesthetics. This dual functionality signifies a significant advancement in urban planning and architectural designs, promoting the integration of renewable energy sources into everyday environments.

Another critical application of glass in renewable energy is in the development of energy storage systems. Glass-based materials are being explored for use in batteries and supercapacitors, due to their superior conductivity and durability. These innovations can lead to more efficient energy storage solutions, enabling better integration of intermittent renewable energy sources like solar and wind. Furthermore, advancements in thin-film technology are allowing glass to be used in flexible solar panels, expanding the potential for solar applications in various settings, including portable devices and remote locations.

As the industry continues to innovate, glass is expected to play an increasingly vital role in enhancing the sustainability of energy solutions. By harnessing its unique properties and exploring new technologies, the renewable energy sector can capitalize on glass's potential to provide cleaner and more efficient energy solutions for the future.

The glass industry is increasingly embracing circular economy practices to promote sustainability and innovation in 2025. By rethinking the lifecycle of glass products, manufacturers are focusing on minimizing waste and maximizing resource efficiency. This involves not only the design of glass products for easier recycling but also the integration of recycled materials into new glass production. The concept of a closed-loop system is gaining traction, where discarded glass is continuously reintegrated into the production process, reducing the need for raw materials and lowering carbon emissions.

Moreover, the adoption of advanced technologies is enabling more efficient sorting and processing of glass waste. Techniques such as automated sorting and AI-powered recycling plants improve the quality and quantity of recycled glass, thus supporting the circular economy. Industry players are also collaborating with other sectors to develop innovative applications for recycled glass, such as in construction materials and decorative products. These initiatives not only mitigate environmental impact but also demonstrate how circular practices can lead to economic opportunities, ensuring a sustainable future for the glass industry.

The glass industry is poised for significant advancements in recycling and waste reduction strategies, crucial for fostering a sustainable future. According to a report by the Glass Recycling Coalition, the recycling rate for glass containers in the United States has reached approximately 33%, highlighting an urgent need for improved collection and processing systems to further increase this percentage. As demand for eco-friendly materials grows, innovations in glass deep processing are being developed to enhance the quality of recycled glass, often referred to as cullet, which is vital for manufacturing new glass products.

Emerging technologies are transforming the glass recycling landscape, with a focus on automated sorting and processing systems that improve efficiency and reduce contamination. The National Association of Glass Manufacturers indicates that a mere 10% increase in recycling rates could significantly reduce greenhouse gas emissions and energy consumption, making recycling a linchpin in sustainable industry practices. Furthermore, initiatives aimed at educating the public about proper recycling practices are beginning to bear fruit, showing that informed communities can lead to better waste management outcomes. As these trends evolve, they signify a shift towards a circular economy where waste is minimized and resources are efficiently utilized.