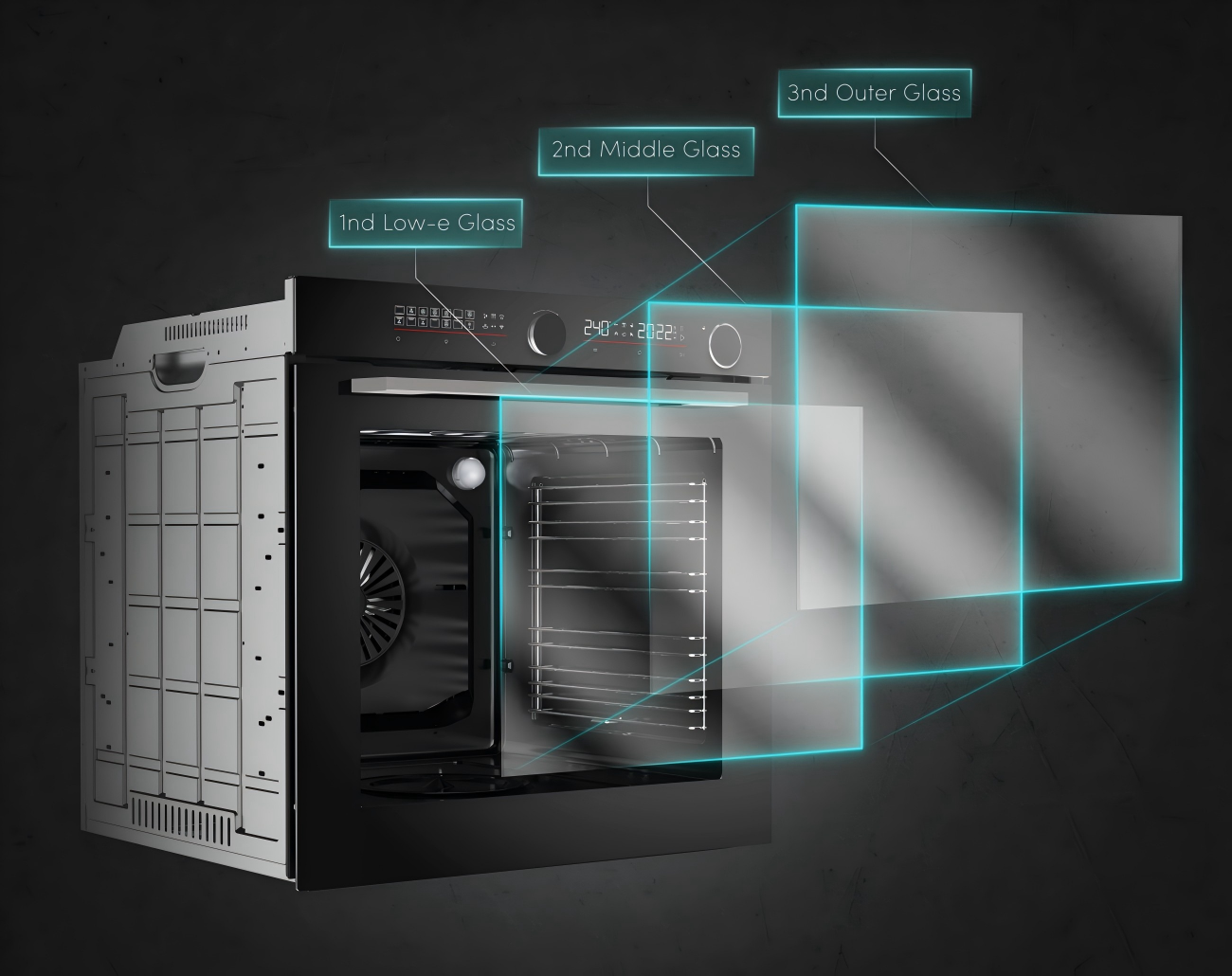

Next-Generation Tempered Cover Glass Redefines Industrial Control Panel Durability

As known that cover glass is a very important mechanical component for Industrial Control panel, which should be engineered to withstand the harshest industrial environments while delivering unparalleled optical clarity and touch sensitivity. Saida Glass keep the path of innovation designing cover glass applied in manufacturing, automation, and smart infrastructure with durability, safety, and performance in industrial display technology.

Technical Breakthroughs for Extreme Conditions

Through chemical tempering and nano-coating technologies to address the core challenges of industrial control systems:

1. Unmatched Strength:

a. Surface compression (CS) exceeding 700 MPaand depth of layer (DOL) up to 35 μm, providing 10x higher impact resistance than conventional float glass.

b. Ball drop test certification: Withstands a 500g steel ball drop from 1 meter without breakage.

2. Environmental Resilience:

a. Chemical resistance: Impervious to acids, alkalis, and solvents, ensuring long-term stability in corrosive environments.

b. Thermal stability: Maintains structural integrity across -40°C to +150°C temperature ranges.

3.Optical Excellence:

a. 92%+ light transmittancewith anti-reflective (AR) and anti-glare (AG) coatings, enabling clear visibility in direct sunlight or low-light conditions.

b. Anti-fingerprint (AF) treatment: Reduces smudges and simplifies maintenance in high-touch applications.

Applications Across Critical Industries

In Saida Glass, cover glass can be customized to tailor for mission-critical systems demanding reliability and precision:

- Industrial Automation: Control panels for CNC machines, robotics, and factory IoT devices.

- Heavy Machinery: Crane, excavator, and agricultural equipment displays, ensuring operator safety in dusty or wet conditions.

- Medical Devices: Sterilization-resistant touchscreens for surgical equipment and diagnostic tools.

- Energy Infrastructure: Solar panel inverters and smart grid monitoring systems.

“Our customers in mining and aerospace have tested our Glass Panel under extreme stress, and the results are transformative,” said Rock, CEO of Saida Glass. “This glass isn’t just a component—it’s a strategic enabler for industries transitioning to digital-first operations.”

Customization

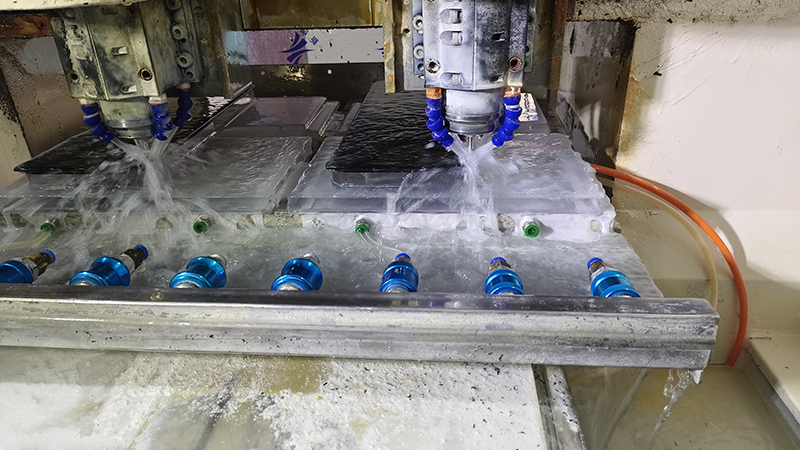

- Thicknesses from 0.33 mm to 12 mm, with precision CNC machining for complex geometries.

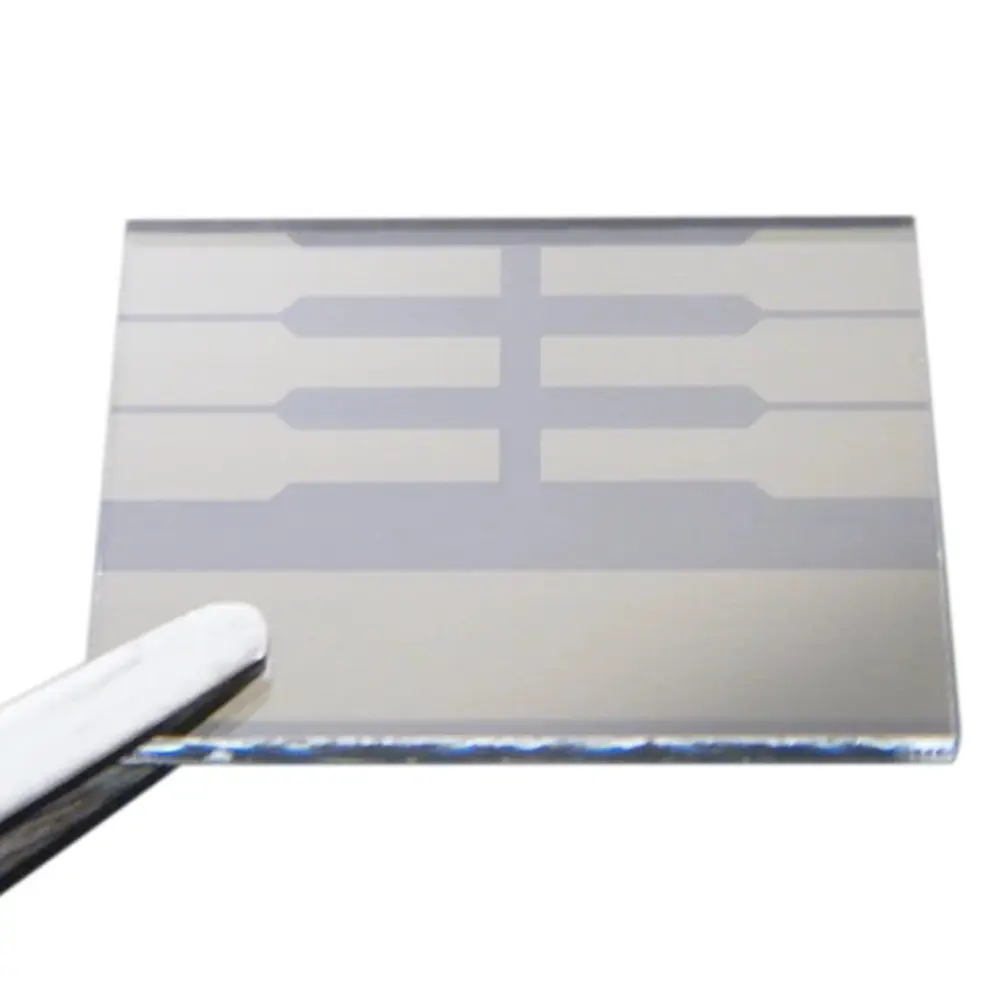

- EMI shielding and conductive coatings for advanced electromagnetic compatibility 3.

- Custom silk-screening and UV printing for branding and functional overlays.

Quality Assurance

- 100% optical inspectionusing advanced metrology tools (stress meters, haze meters) .

- AQL 0.25 compliancefor dimensional accuracy.

- ISO 9001 certification& automatic production line, ensuring stable quality operation.

Why Choose Saida Glass?

- Proven Performance: Field-tested in partnership with Fortune 500 industrial equipment manufacturers.

- Cost Efficiency: Reduces downtime and replacement costs compared to traditional polycarbonate solutions.

- Solution: 20+ engineer team that can provide perfect solutions according to your design.

For technical specifications, case studies, or a free sample, please visit https://www.saidaglasses.com/ or contact: sales@saidavn.com.

About Saida Glass

Saida Glass specializes in precision glass processing for high-tech industries, offering end-to-end solutions from design to mass production. With 14+ years of expertise and partnerships with Corning® and AGC®, we deliver innovation that drives industrial performance.

Phone

Phone Send Email

Send Email whatsapp

whatsapp Facebook

Facebook