Precision Engineered Mirror Glass-One / Two Way

As a specialized deep-processing glass manufacturer, we develop technical Mirror glass solutions that bridge optical excellence with industrial robustness. Our products undergo rigorous physical/chemical enhancements to address critical challenges in light management, environmental resistance, and structural integration.

Mirror Glass Technical Specifications

| Category | Technical Attributes | Industry Alignment |

| Base Material | • Low-iron float glass / Ultra-cleAr Glass | Optical, Automotive, Medical |

| Thickness Range | 1.1mm – 19mm (±0.15mm tolerance) | Architecture, Industrial HMI |

| Surface Reflectivity | • 70%, 60%,50% | Monitor |

| Flatness Precision | • Industrial grade: <0.3%/m² | Astronomy, Semiconductor |

| Thermal Resilience | • Continuous operation: -30°C to +150°C | Automotive, Aerospace |

| Surface Hardness | • Chemically strengthened: 7H-9H (Pencil) | Touchscreens, Appliance fascias |

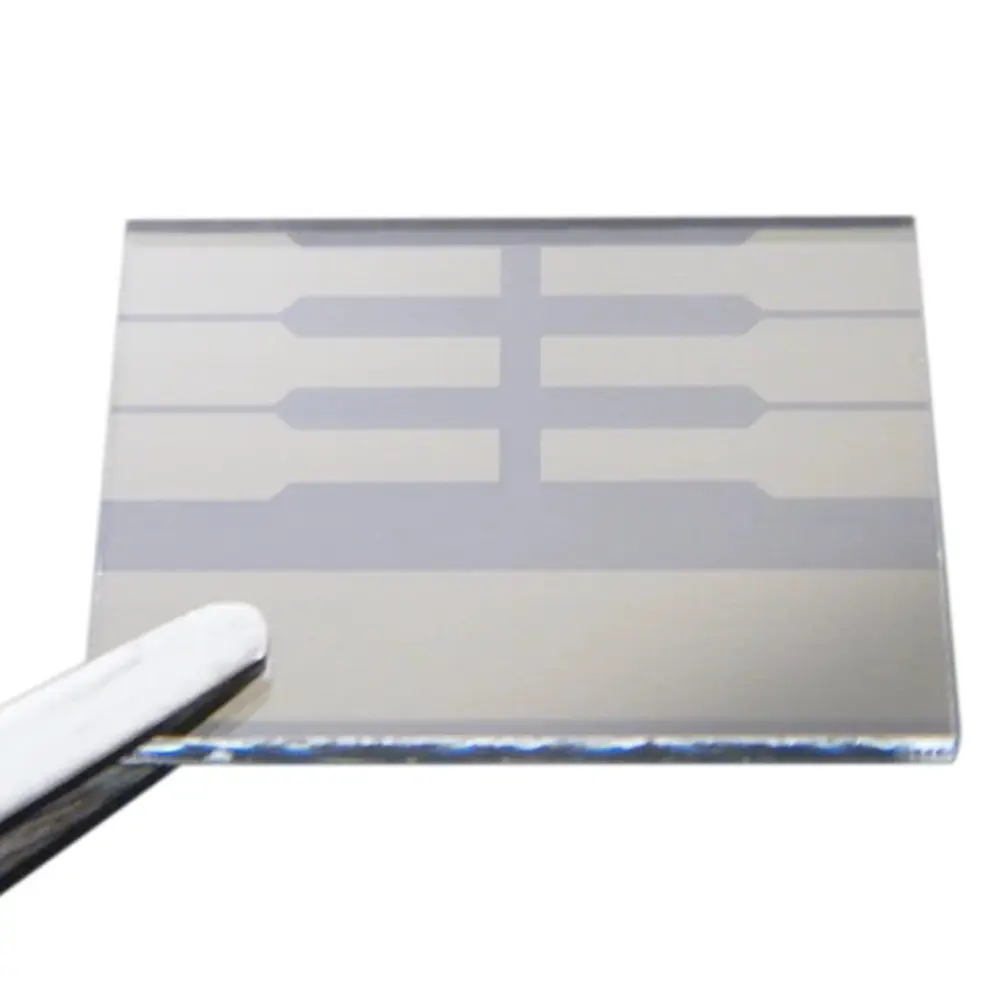

| Functional Coatings | • Conductive ITO (≤100Ω/sq) | Smart devices, Military optics |

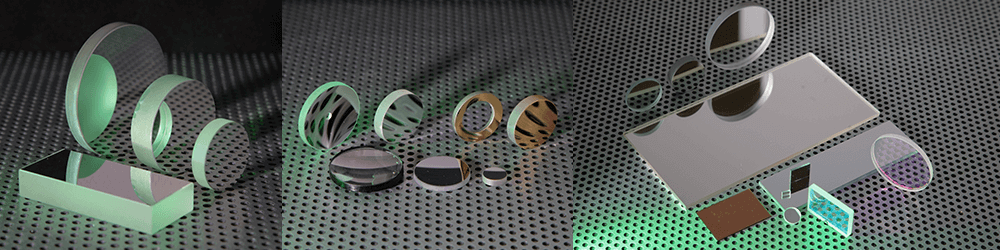

Optical & Scientific Instrumentation

Engineered for high-precision optical systems requiring non-compromised light control:

Spectrum-Specific Coatings: Customizable dielectric layers optimized for UV/VIS/IR reflectance performance

Surface Integrity: ≤0.3%/㎡ flatness for beam steering accuracy

Typical Integration:

▶ Laser path alignment modules

▶ Spectral analysis equipment mirrors

▶ Medical endoscope reflector assemblies

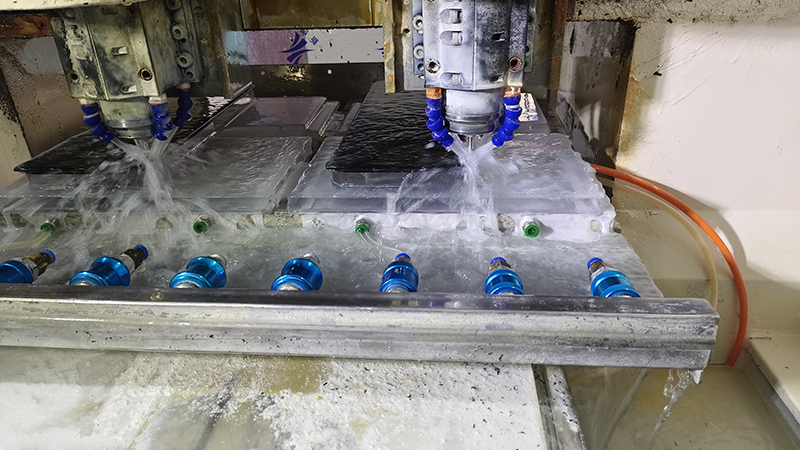

Automotive & Industrial HMI Solutions

Reliable performance under vibration, thermal cycling, and chemical exposure:

Smart Surface Ready: Conductive coating options for touch-integrated displays

Environmental Resistance: Chemically toughened surfaces withstand abrasive particulates

Implementation Scenarios:

▶ Autonomous vehicle perception system housings

▶ CNC machine HMI protective overlays

▶ Aircraft cockpit display anti-glare layers

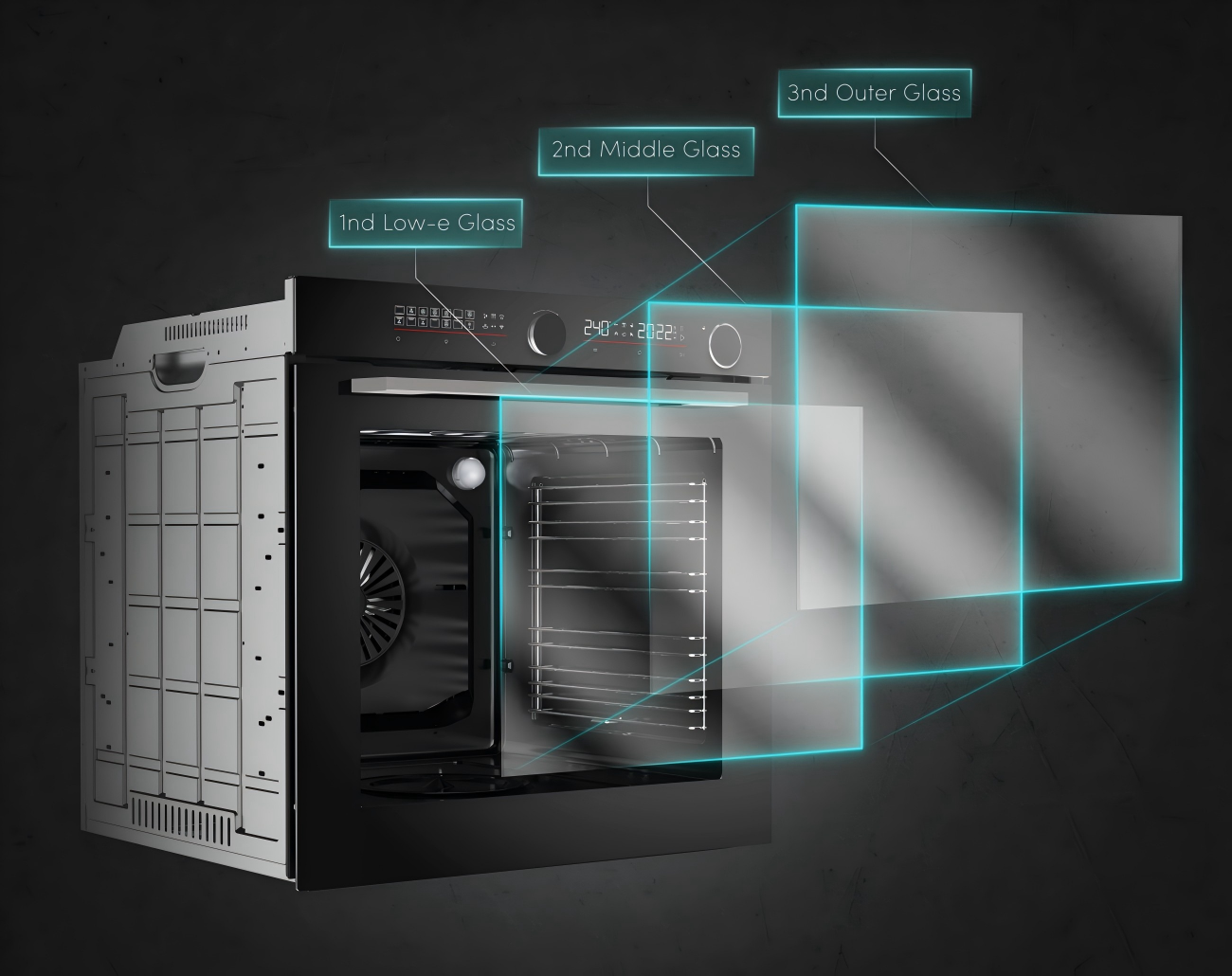

Architectural & Consumer Electronics

Aesthetic intelligence meeting functional demands:

Durability Engineered: Hard-coat anti-abrasion surfaces (pencil hardness ≥9H)

Climate Adaptive: Humidity-resistant silvering backed by copper-free processes

Design Flexibility: Custom curvature forming (hot bending & cold shaping techniques)

Application Innovations:

▶ Voice-controlled smart mirror interfaces

▶ Commercial refrigeration glass doors with anti-fog properties

▶ Acoustic-rated mirror wall systems

For further learning about our capabilities, please visit our website for reference: www.saidaglasses.com .

For OEM/ODM partnerships in specialized mirror applications, welcome to contact for technical discussions: sales@saidavn.com

Phone

Phone Send Email

Send Email whatsapp

whatsapp Facebook

Facebook